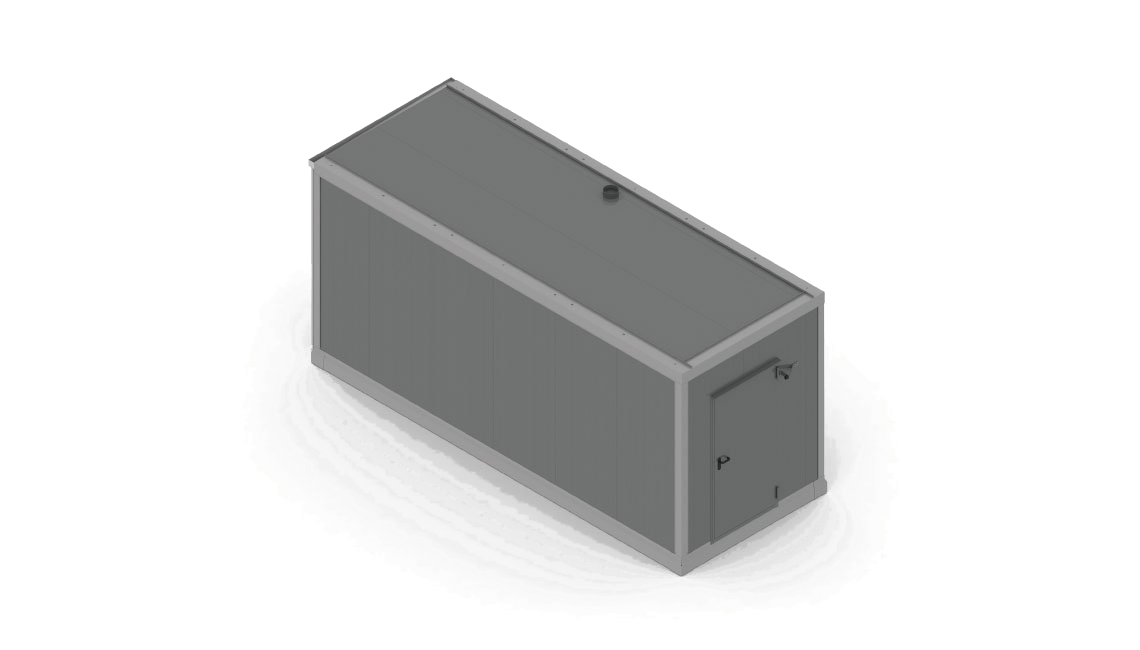

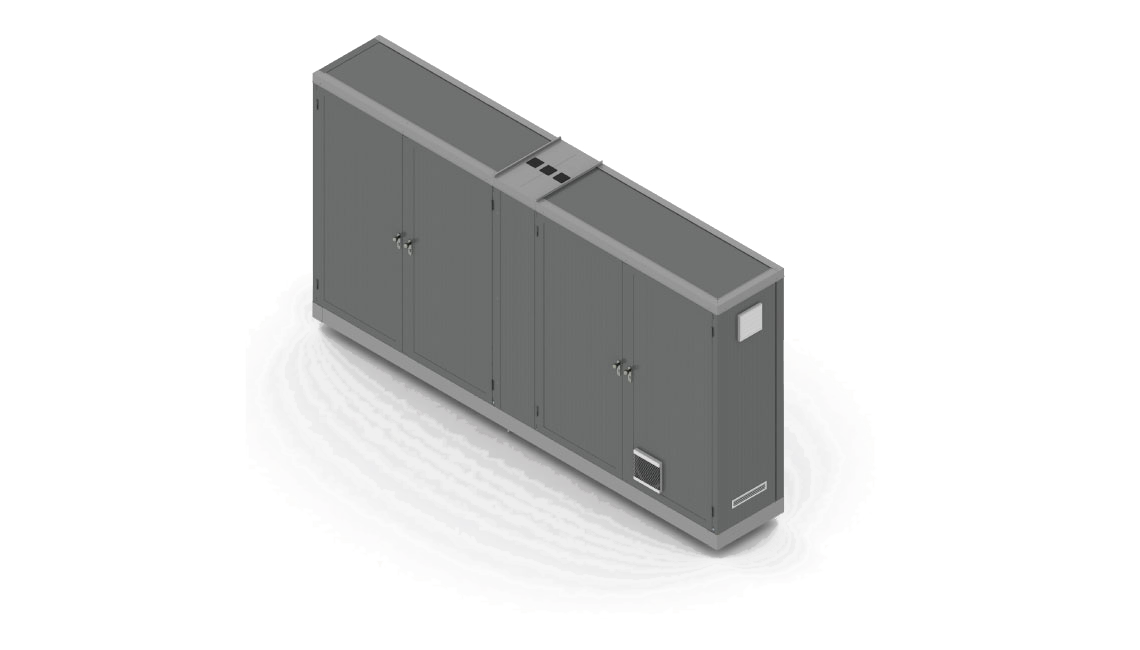

Christ technique container

For housing the supply technique when no plant-room can be provided by the customer.

Technique container, walk-in, for up to 7 wash bays

Entrance to lockable access door on front side of container. The container walls consist of sandwich elements in white aluminium RAL 9006.

COMPACT technique container, cabinet construction, for up to 3 wash bays

Entrance via four lockable cabinet doors on side of container (container can not be entered). The container walls consist of sandwich elements in white aluminium RAL 9006.

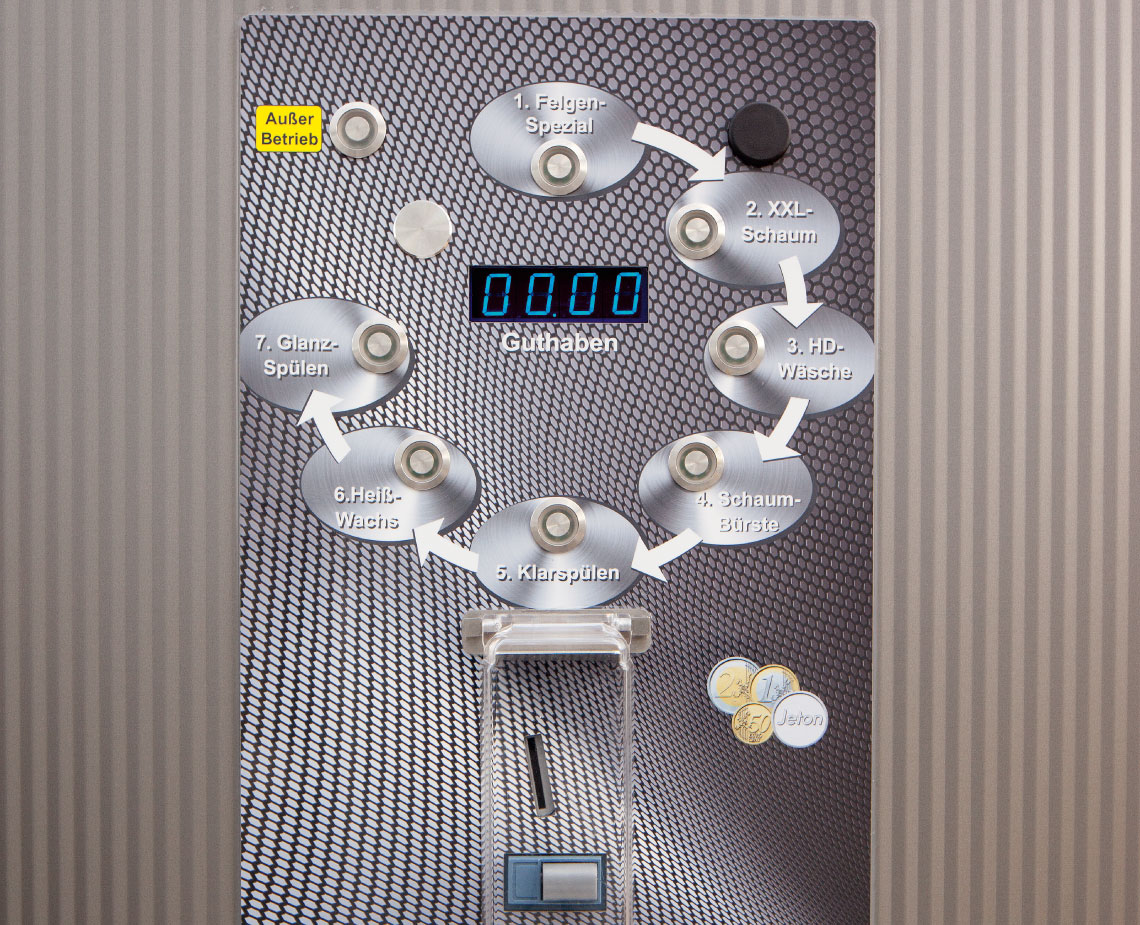

Operator-friendly wash program selection

Blue illuminated program selection buttons allocated in clockwise sequence and a LED-display for displaying the money amount and remaining money amount are user-friendly. The electronic coin examiner accepts coins and tokens. An alarm device can be integrated in the casing which is always protected from frost and splash water.

UBT WPS installed in container

Installation solution for wash bays adjacent to the technique container.

UBT WPS

BASIC

Modern, free-standing operator panel in clear design with side cover plate for easy maintenance and access to the coin examiner. Can also be obtained as wall installed version upon request.

PREMIUM

Front and side metal sheets made from stainless steel are mounted for additional protection against vandalism.

High-pressure lance with holster

Ergonomic and sturdy high-pressure spray lance used for the wash programs high-pressure precleaning, clear rinse, hot wax conservation and gloss rinse. Holster frame made from stainless steel.

Foam brush with lance holster

Lance with attached soft foam brush used for the wash program foam brush basic cleaning. Holster frame made from stainless steel.

Combi-lance holster for high-pressure lance and foam brush

This special holster is used in connection with a double deck rotary head (e.g. in open-air wash bay) and can receive the high-pressure lance as well as the foam brush. The holster frame is made from stainless steel.

XXL-Foam lance with lance holster

Ergonomic and easy foam spray lance especially for application of XXL-foam (for excellent foam and lowered chemical consumption). The holster is made from stainless steel.

Single deck rotary head, 360° slanted system

Can be combined with the high-pressure lance, XXL-foam spray lance and foam brush. Designed in stainless steel with a swiveling range of 360° for tangle-free swiveling.

Double deck rotary head

For receiving the high-pressure lance and foam brush (e.g. in open-air wash bay). Made from stainless steel with a swivelling range of 360

Open-air wash bay attachment kit

Bracket made from steel, galvanized, passage height 4.000 mm. The attachment kit is prepared for mounting the double deck rotary head.

Cost-effective low-pressure operation

The wash programs: hot wax and gloss rinse are serially operated using low-pressure (3 bar) and reduced water quantities (savings potential of up to 80% in comparison to high-pressure operation) for saving water, electricity and wash chemicals. Hot-wax and permeate can be applied more precisely and without mist hindering the customer’s vision. The operator can share his cost savings with customers by increasing program running time and in doing so increase customer loyalty. The customer gets more for his money.

High-pressure supply

The maintenance-friendly high-pressure pump cabinet is mounted with high quality piston pumps. The powerful pump produces a working pressure of approx. 85 bar at 10 ltr./min. with its 950 rpm.

The high-pressure pump cabinet can also be mounted in a customer provided technique container. A compact device is separately mounted on a console for each wash bay. The required armatures and dosing pumps are situated on the same installation level. High-quality components and pipe made from stainless steel guarantee long life duration and best possible functionality.

Condensed boiler heating unit

Christ uses environmentally friendly heating technology to reduce heating costs. This technology guides accumulated exhausted emissions produced when burning oil or propane additionally over a heat exchanger. The heat won during this procedure is being used for warming water. This saves energy and consequently money. Should the operator wish to install customer-provided solar

collectors on his wash bay roofing, a corresponding connection can be installed in the heating unit in order to supply the heat won through solar irradiation to the heating unit.

Plate heat-exchanger

Heat transfer from the heating unit’s heating circuit distributor to the separate high-pressure supply water feed. Integrated floor heating can be additionally installed in the wash bay foundation (wash plate) by providing the necessary connection. Floor heating prevents ice from forming on the wash plates.

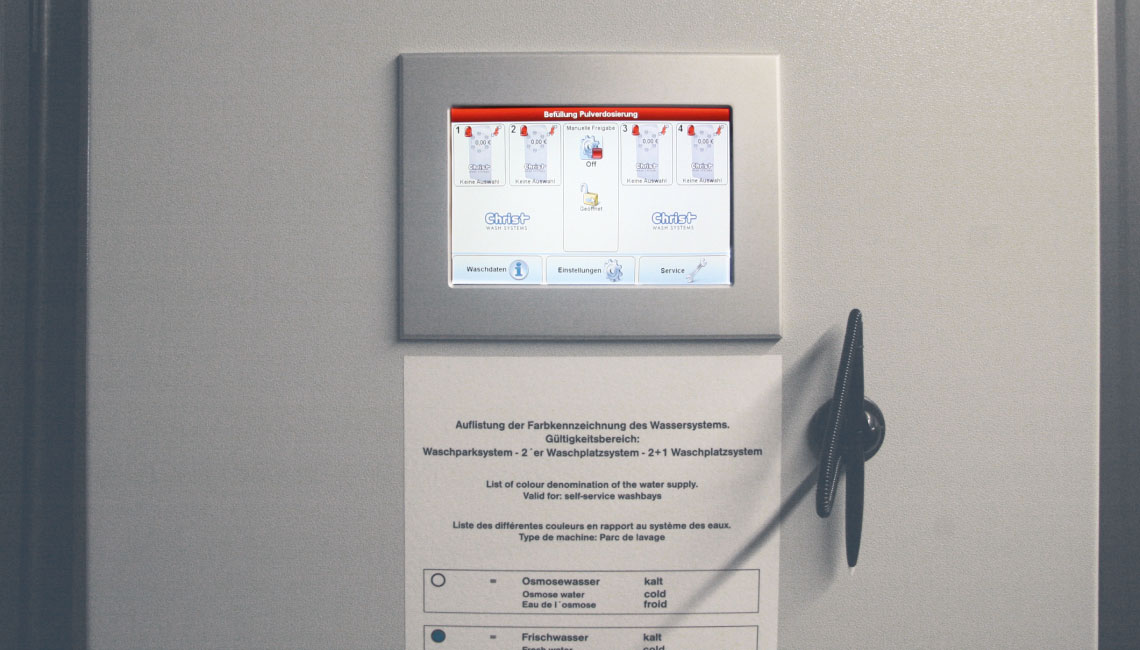

„TOUCH ME“ Touch screen control

Simple and clearly laid out operator access via the central touch screen operator panel. The panel is integrated in the door element of the control cabinet. Operation succeeds by touch or using the

touch pen attached on the side. Required information and settings can be easily found and changed. Should an internet connection to the operation site’s switchgear cabinet be provided, then the

operator surface can also be accessed via internet remote access. This enables adjustments or profit inquiries to be made without having to be physically present on site.

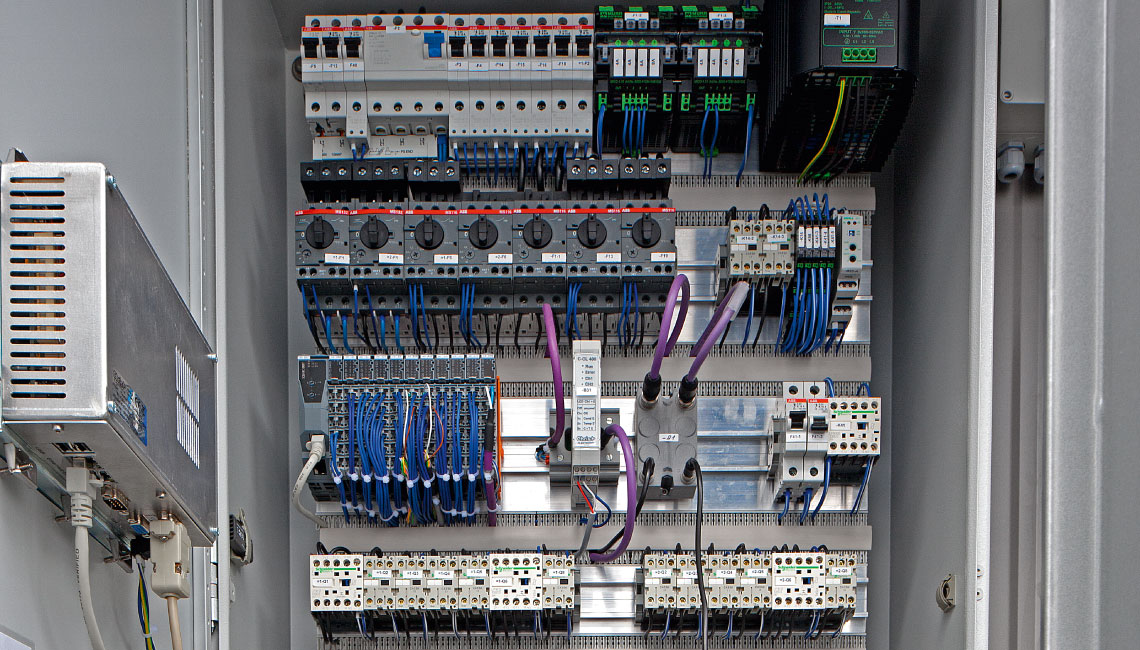

Switchgear cabinet

A guarantee for safe control and unit monitoring.The freely programmable memory control (PLC) enables future retrofittings to be easily implemented. The PLC, the completely wired 400V power stack, the motor protection switch and the frequency converter are installed in the protected, painted sheet steel switchgear cabinet.

Bay illumination

Energy-saving LED flat spotlights provide optimum lighting in the wash bay.

Money changer with receipt printer

Accepts bills and coins, dispenses coins or tokens for cash-free washing in wash parks.

Warm water extraction point

Warm water dispensing at charge. For wash customers who prefer washing with their own sponge.

Wash Manager Payment System – more than just a money exchanger

The valuable pay machine with stainless steel front plate and built-in 8,4” bullet-proof glass touch screen (15” also available) is designed for most comfortable handling.

This device enables:

– Money changer for coins and bills (output of coins or tokens possible)

– Purchase of chargeable customer cards (with integrated transponderchip), card issued upon payment of automat deposits

– Charging of bought customer cards direct on pay machine with a selectable money amount. For use as debit card

– The higher the card is charged, the higher the debit bonus can be set (e.g. charged with 50 Euro = 10% bonus credit; therefore, the card has a sum of 55 Euro).

Advantages for the wash bay operator:

– Customer loyalty

– Interest-free credit for the operator through the prepaid process

– Cash-free operation of the operation device possible (customer paid w/o customer card on the operating device’s coin examiner with tokens. Tokens are handed out by the money changer on the pay machine)

Further advantages:

The pay machine can also be used for controlling a roll-over wash unit (installation of the device in the wall at the entrance of the roll-over unit). The desired roll-over unit wash program can be

selected on the touch screen and can be paid for either with cash (coins or bills) or with a customer card. For connecting to a Christ roll-over unit, only a UBT-S and a Wash Manager Interface are

required.

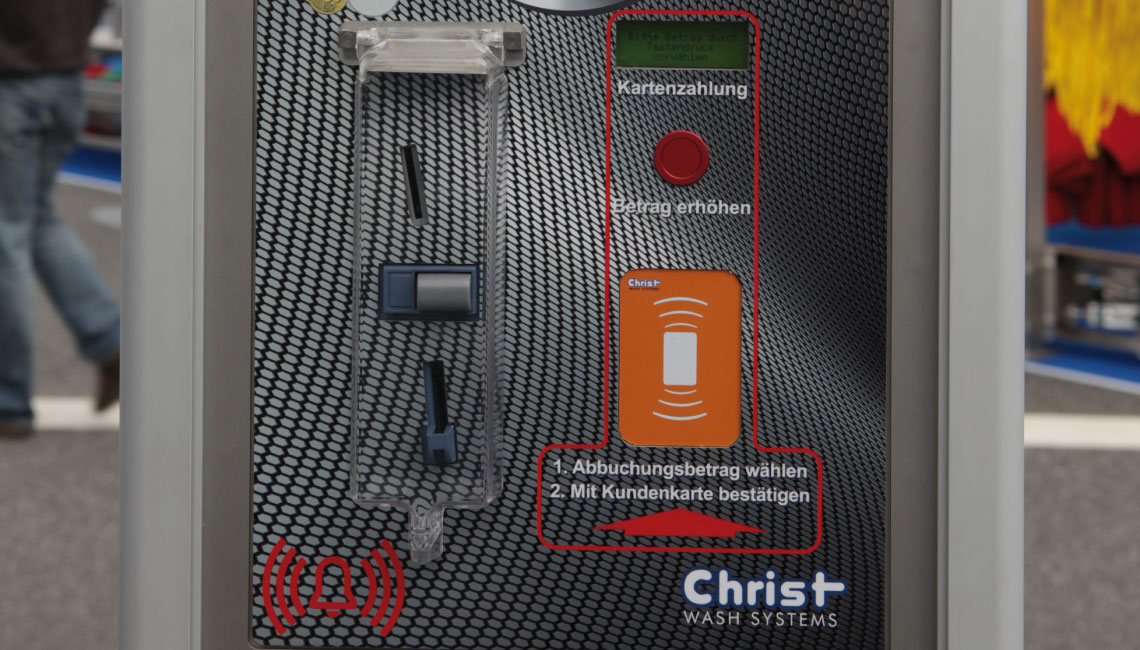

Card payment on self-service wash bay

In the operation device UBT WPS, a card reader with a pre-selection button for debiting a certain money amount and an indication display (shows card credit amount or pre-selected debit amount.

Once having pre-selected the money amount and held up the charged customer card, the amount is transferred to the UBT. The money amount is displayed on the LEDdisplay field and can be used

for washing.